PROJECT: HOOK ATTACHMENT AND CHASSIS GROUNDING

OVERVIEW:

Designed and prototyped a hook attachment for gasket sealing, tested o-rings for durability, 3D-printed prototypes, and prepared chassis for coating and finishing.

SKILLS:

SolidWorks, 3D printing, Machine Shop Manufacturing

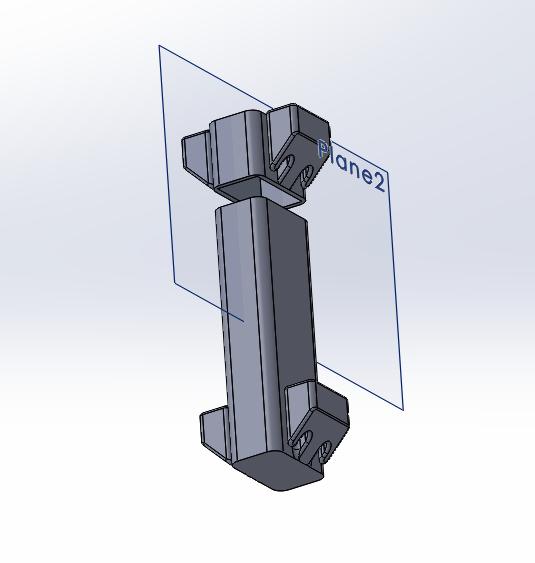

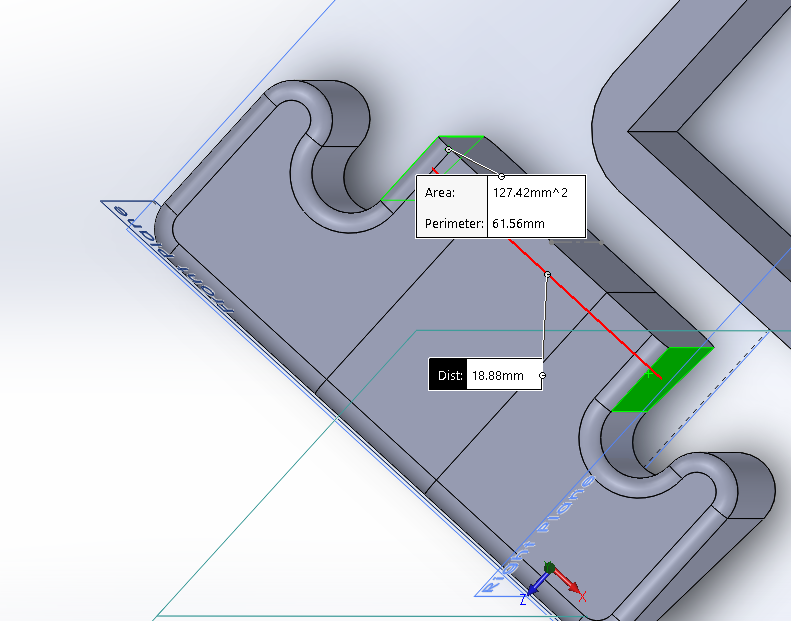

DESIGN AND PROTOTYPING

Worked with a subteam to design a hook attachment in SolidWorks to ensure the gasket would seal properly under load. Multiple iterations were created, accounting for geometric tolerances and fit within the chassis assembly. To validate the design, several prototypes were 3D printed using Prusa printers and presented to the chassis team leads for review, ensuring the attachment met both functional and manufacturability requirements.

MATERIAL TESTING AND ANALYSIS

Performed stress testing on various o-ring types to evaluate their performance under compression. Using a weight-based setup, calculated the modulus of elasticity, observed material wear and tear, and determined the optimal o-ring size and material for sealing effectiveness. This testing process provided data-driven justification for material selection and helped refine the attachment design to achieve reliable long-term sealing.

MANUFACTURING PREPARATION

Oversaw preparation of chassis components for powder coating and anodizing, processes that require proper grounding and surface finishing. Utilized a Dremel to prepare the chassis floor and ensure precise fit of components prior to coating. These steps enhanced coating adhesion, durability, and ensured the final assembly maintained both structural integrity and professional finish.