PROJECT: FLAPPY BIRD TOY

OVERVIEW:

Tasked with designing a viable toy design for SpinMaster Ltd. Developed a fully functioning toy inspired by the Flappy Bird mobile game using machining and 3D printing components using SolidWorks.

SKILLS:

Mechanical Design, Prototyping, User Experience, Manufacturing

DEMO:

WATCH DEMODOCUMENTATION:

TECHNICAL REPORTMECHANISM DESIGN

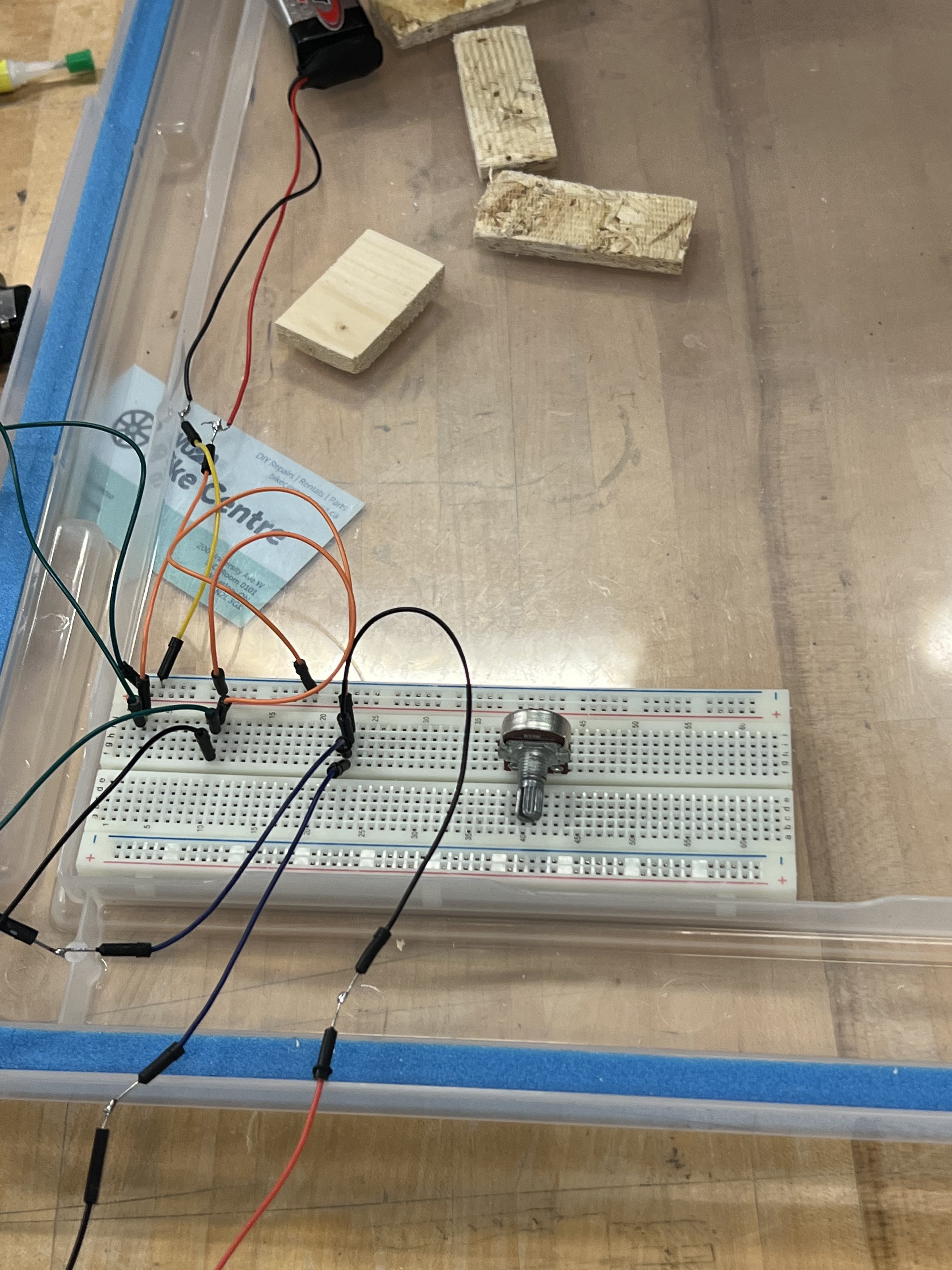

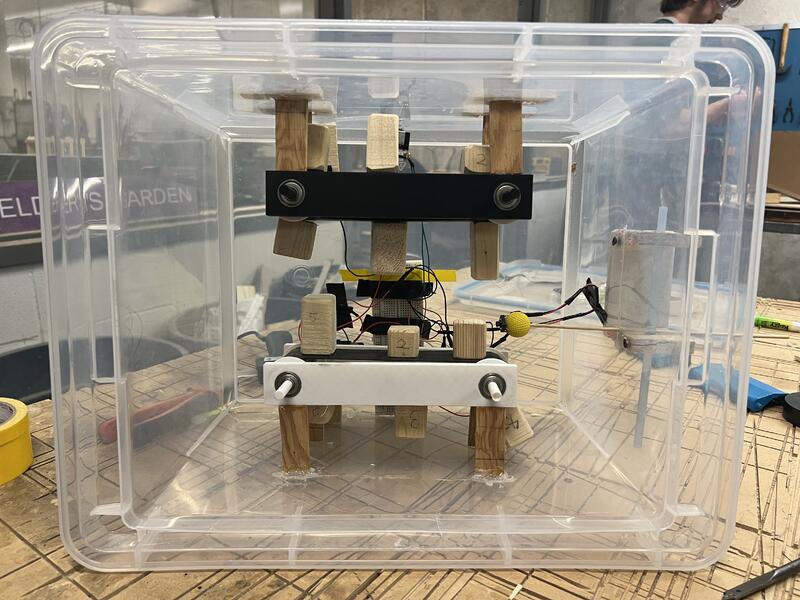

Developed the core gameplay system by designing and prototyping conveyor belts to simulate moving obstacles, a vertical slider to control the “bird,” and an automatic stopping mechanism for loss detection. Designed gears, shafts, and supports in CAD, using 3D printing and bearings to ensure smooth motion and stable operation. Iterated multiple concepts (e.g., pulley-driven bird vs. slider system) and selected the simplest, most reliable design to balance functionality, responsiveness, and durability.

USER INTERACTION

Translated the digital Flappy Bird mechanics into a tactile play experience by creating an intuitive control system. Players manipulate a stick-and-slot mechanism to move the bird up and down, mimicking the original game’s challenge while maintaining simplicity for the target age group (6–12). Integrated a pushbutton collision sensor so the game immediately stops upon loss, providing clear feedback and aligning with safety requirements. Focused on ensuring responsive, smooth, and repeatable interactions to keep gameplay engaging.

MANUFACTURING OPTIMIZATION

Refined prototypes to meet cost, safety, and playability constraints while considering manufacturability. Simplified the bird movement from a motorized pulley system to a low-cost manual slider for reliability and ease of assembly. Optimized conveyor belt design using bike tubes as an affordable substitute for standard belts, and adjusted tolerances in gears and shafts to ensure smooth fit with TT motors. Evaluated durability of materials and assembly methods (e.g., adhesives, slot dimensions) to minimize wear, simplify construction, and improve long-term usability.