PROJECT: FORMULA 1 FRONT WING

OVERVIEW:

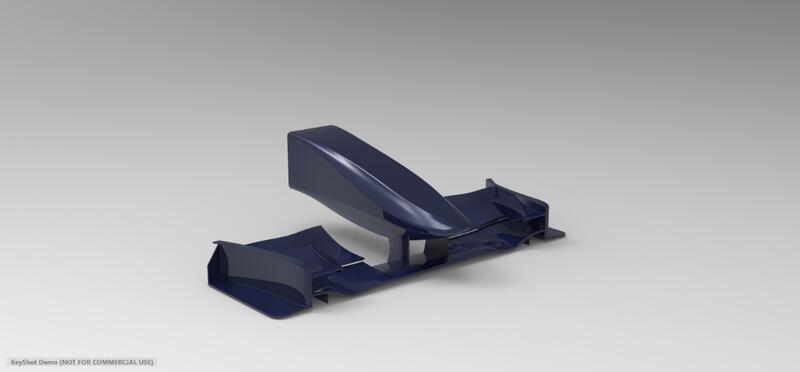

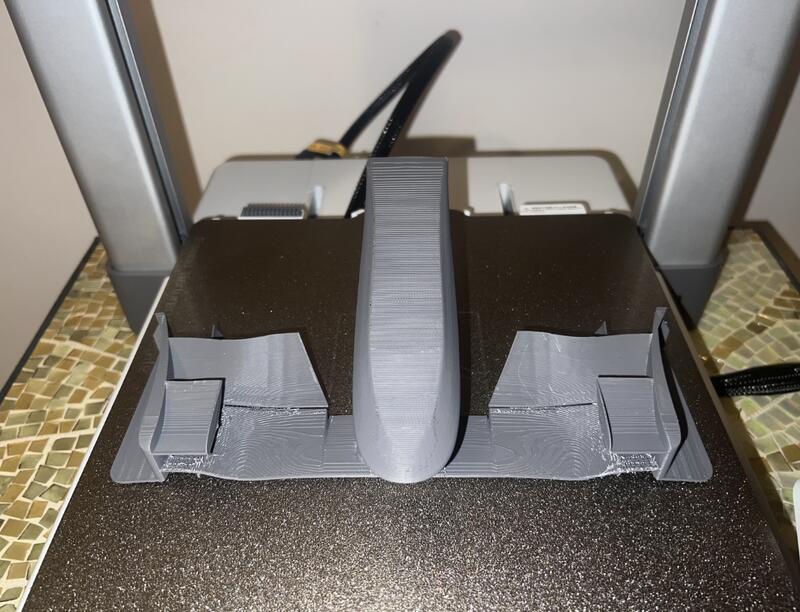

Recreated and modelled the Williams FW31 Formula 1 front wing in SolidWorks, producing photorealistic renders in KeyShot and running CFD flow simulations to assess aerodynamic characteristics. Fabricated a physical prototype using a Bambu A1 3D printing system.

SKILLS:

CAD, CFD, SolidWorks, KeyShot, 3D Printing, Aerodynamics

CAD MODELING

The project began with creating a precise 3D model of the front wing in SolidWorks. The most frequently used tool in the design process was the spline tool. This project exposed me to a wide array of advanced features, including boundary surface, lofting, surface knit, surface offset, replace face, and surface trim, among others. I also gained a deeper appreciation for the use of reference planes, which significantly streamlined the modelling process. To add realism and visual appeal to the model, I used KeyShot Studio to render the design and applied the signature vintage Williams dark blue livery.

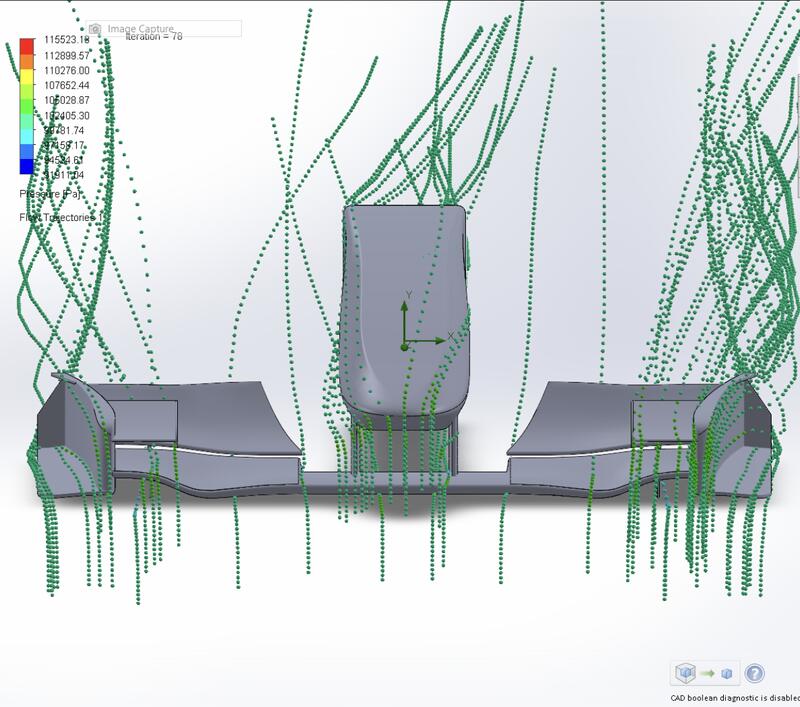

CFD ANALYSIS

The flow simulation results displayed excellence by Williams. In Formula 1, the ideal front wing design maximizes downforce while minimizing aerodynamic drag, improving tire grip and allowing for high-speed cornering. The simulation data indicated an average downforce of 3000 N and a drag force of 1500 N. As seen in the simulation images, you can see that the wing forces the air to travel to the side of the car and avoid the front tires, and the nose of the front wing has relatively low pressure points (no red air points). The fillets on the nose also allow for the air to travel along the side of the nose (more efficient), as opposed to going straight up and creating unwanted downforce. An important observation is the airflow beneath the front wing — a critical factor, as teams aim to funnel this air towards the rear diffuser under the floor. When the simulation is animated, the airflow deflects off the wing and transitions toward the sidepods, which have holes to allow air to reach the radiators that manage engine cooling.

PHYSICAL PROTOTYPING

A physical prototype was fabricated using a Bambu A1 3D printing system. The prototype allowed for physical validation of the design and provided a tangible representation of the complex aerodynamic geometry.