PROJECT: ROPE BRAKE DYNAMOMETER

OVERVIEW:

Successfully built a rope brake dynamometer to measure the torque of a TT motor using metal connections and pulley systems. Completed a technical report to present equations and model relationships.

SKILLS:

Mechanical Testing, Data Acquisition, Instrumentation, Calibration

DOCUMENTATION:

TECHNICAL REPORTMECHANICAL DESIGN & EXPERIMENT SETUP

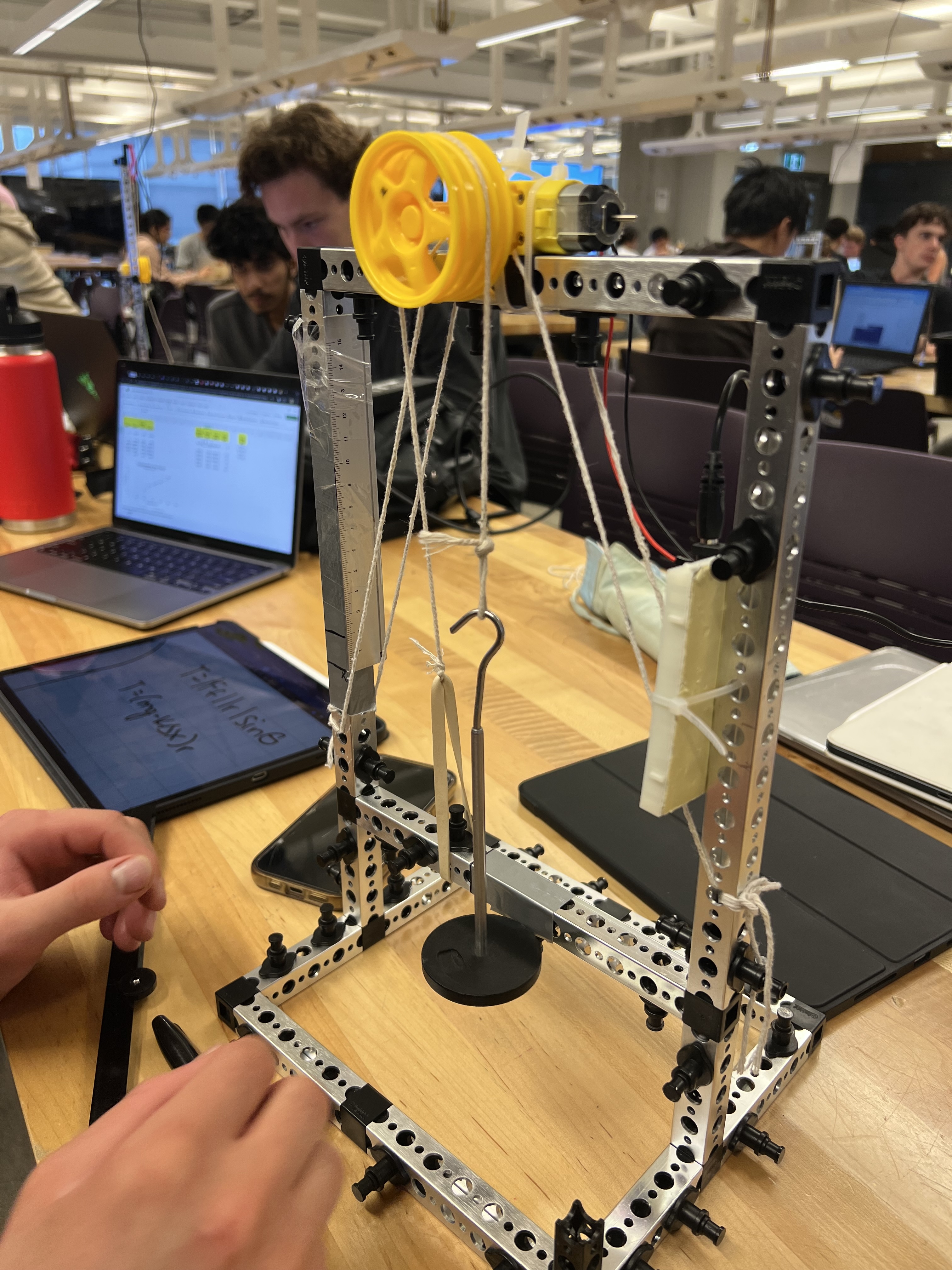

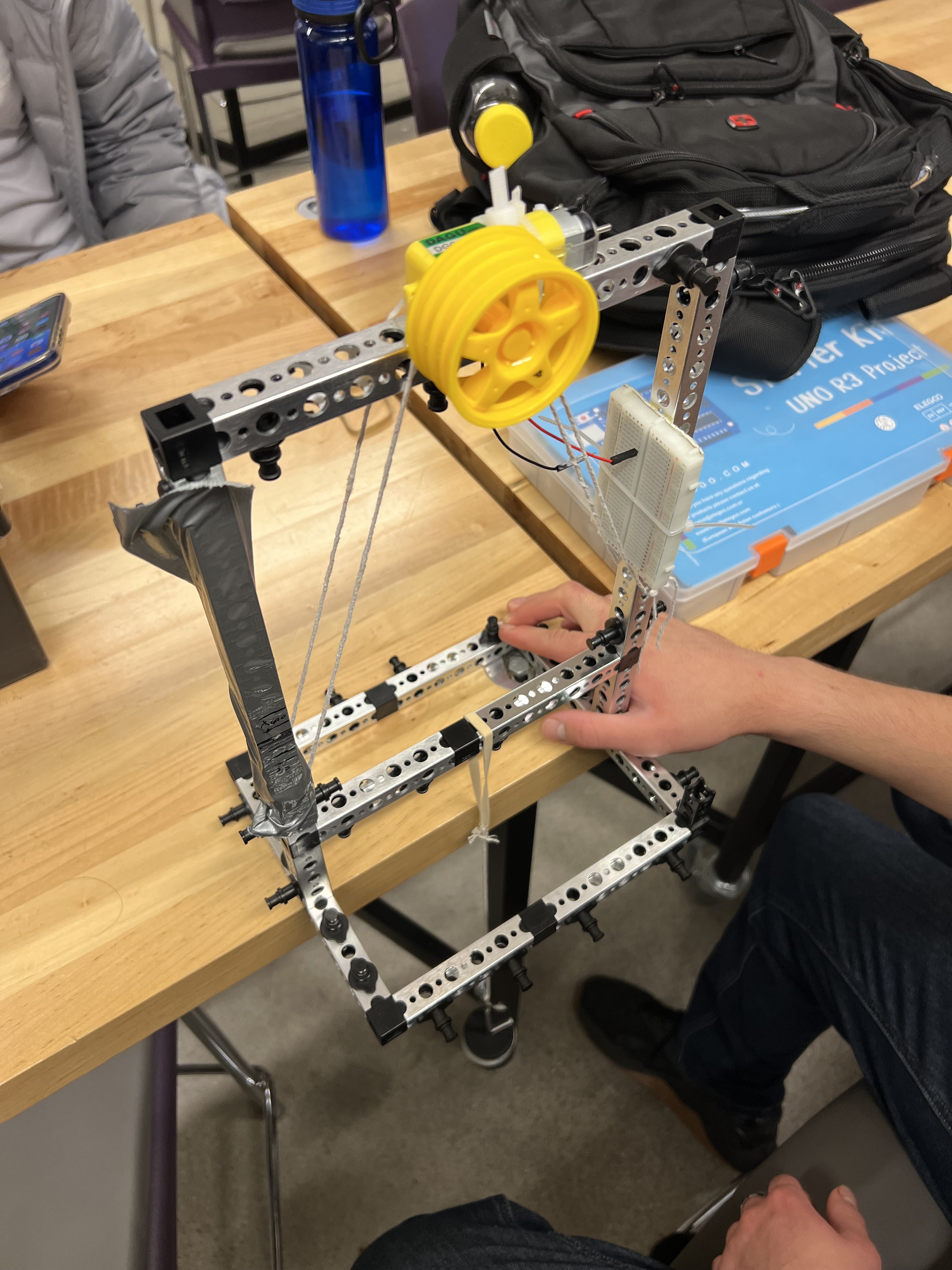

Designed and constructed a rope-brake dynamometer to test the torque–speed characteristics of a DC motor. Integrated a custom base structure, wheel, rope system, and elastic spring acting as a load cell. Applied Hooke’s Law to translate spring displacement into force readings, enabling torque measurement. Optimized stability with structural modifications and motor mounting reinforcements to reduce noise and ensure accurate experimental results.

CALIBRATION & DATA ACQUSITION

Conducted calibration of the elastic spring load cell by suspending known weights and recording displacement, deriving the spring constant through regression analysis (R² = 0.98). Used slow-motion video analysis to determine motor no-load speed and collected torque-speed data across varying load conditions. Implemented error-checking and repeated trials to validate data consistency and reliability.

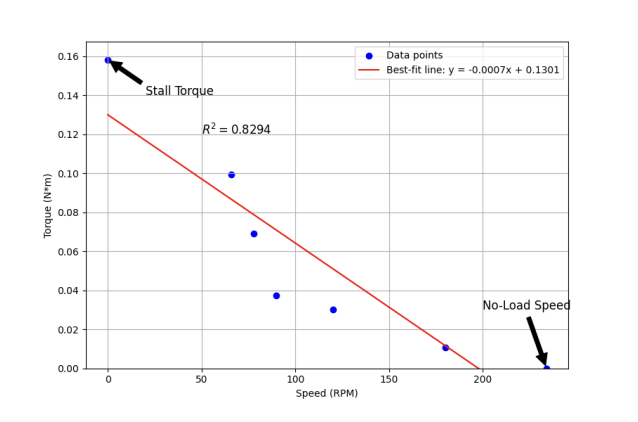

DATA ANALYSIS AND PERFORMANCE EVALUATION

Analyzed torque-speed characteristics of the DC motor, producing a linear fit with R² = 0.83 that aligned with theoretical expectations of inverse torque-speed relationships. Extracted key motor performance parameters, including stall torque (0.16 Nm) and no-load speed (234 RPM). Critically evaluated data quality by identifying sources of error such as rope friction, spring fatigue, and motor shaft distortion, and proposed refinements for improved accuracy in future iterations.